- Nov 08, 2018 One is traditional PID and another is adaptive fuzzy PID. After that the control system proposed was simulated on an advanced process control system named SMPT-1000. To find out the performance of the adaptive fuzzy controller, one experiment by using three conditions, normal control, disturbance control and load change control, has been.

- As a PID controller would. + + + Figure 1.1 Fuzzy PID System Block PID+FUZZY CONTROL The function of Fuzzy Logic is to adjust PID parameters internally in order to make manipulation of out-put value MV more flexible and adaptive to various processes. The Fuzzy Rule may work like this:. If the temperature differ-ence is large, and the tem.

- Most PID controllers sold today incorporate auto-tuning functions. Operating details vary between manufacturers, but all follow rules where the controller “learns” how the process responds to a disturbance or change in set point and calculates appropriate PID settings.

- Roy, P., Roy, B.K.: Fractional order PI control applied to level control in coupled two tank MIMO system with experimental validation. Control Eng. Pract. 48, 119–135 (2016)CrossRefGoogle Scholar

- Li, Z., Xiao, D.: A fuzzy adaptive PID controller based on neural network. Control Decis. 3, 340–345 (1996)Google Scholar

- Wang, Y.-G., Xu, X.-M.: Adaptive and optimal PI controller with robustness. Acta Autom. Sin. 35(10), 1352–1356 (2009)CrossRefGoogle Scholar

- Yang, X.-J.: The design of intelligent PID controller based on fuzzy theory. Manuf. Autom. 35(3), 115–117 (2013)Google Scholar

- Zou, T., Sun, H.-J., Zhang, X., et al.: An implementation of split control strategy for multi-variable predictive control. Control Decis. 32(4), 746–750 (2017)Google Scholar

- Cherrat, N., Boubertakh, H., Arioui, H.: An adaptive fuzzy PID control for a class of uncertain nonlinear underactuated systems. In: International Conference on Modelling, Identification and Control. IEEE, pp. 677–682 (2017)Google Scholar

- Ji, H., Tian, M.: Analysis and Calculation of Shell and Tube Heat Exchanger. Science Press (1996)Google Scholar

- Yu, L.: Engineering Fluid Mechanics. China Machine Press (2015)Google Scholar

- Ding, D.-J., Wang, Y.-G.: Modeling in frequency domain and controller parameter tuning for industrial processes. Control Eng. China 23(11), 1714–1718 (2016)Google Scholar

- Mahapatro, S.R., Subudhi, B., Ghosh, S.: Adaptive fuzzy PI controller design for coupled tank system: an experimental validation. IFAC Proc. Vol. 47(1), 878–881 (2014)CrossRefGoogle Scholar

- Wang, H., Zhao, S., Gu, J.: Development and application of fuzzy adaptive PID function block based on SCL. Ind. Control Comput. 25(2), 73–74 (2012)Google Scholar

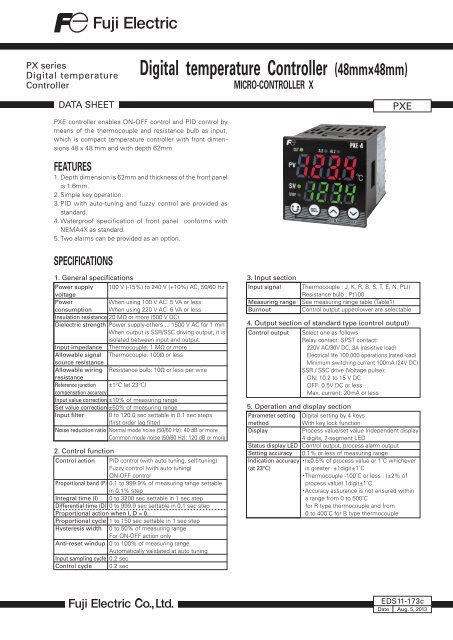

Pid Controller Autotuning

It is difficult to accurately estimate the dynamic model and design a general purpose temperature controller for achieving good control performance. Here model-free auto-tuning and fuzzy PID control strategies are employed to design a general temperature controller for different plants. Page 2 of 131 Warning Symbol This document contains notices that you should observe to ensure your own personal safety, as well as to protect the product and connected equipment.